1. Introduction

Agarwood is a highly prized non-timber forest product which can be used in fragrances, incense, medicines, aromatherapy and religious ceremonies [

1,

2,

3]. The precious, expensive, fragrant agarwood has been used for centuries as incense in Buddhist, Hindu and Islamic ceremonies. It also plays an important role in Chinese Traditional Medicine for obvious medicinal effects as a sedative and carminative, and to relieve gastric problems, coughs, rheumatism and high fever. The essential oil is a highly demanded ingredient in deluxe perfumery for its warm, unique balsamic notes with sandalwood-ambergris tonalities. The value of agarwood shipped out of Singapore alone each year has been estimated to exceed $1.2 billion [

4]. The most important source of agarwood is the

Aquilaria spp. tree, which is an angiosperm within the Thymelaeaceae family [

5]. Agarwood-producing species are found only in the areas ranging from India eastwards throughout the Southeast Asia, as well as in southern China, with Indonesia and Malaysia being the two major countries as the origin for agarwood.

A. sinensis is the main source of agarwood formation in China. According to some historical records, Dongguan City (Guangdong Province, China) abounded in agarwood 400 years ago; its agarwood trade was so very well-developed that raw agarwood products were transported to the Southeast Asia and even as far as Arabia. In fact, Hong Kong is literally named the “Fragrant Harbour” as it was one of the significant trading centers for agarwood and incense in the early days, when

Aquilaria sinensis was widely traded in Hong Kong and then transported to numerous Chinese provinces, Southeast Asia as well as Arabia, along with other incense and spices [

6].

The healthy wood of

Aquilaria trees is white, soft and without scented resins. In a natural environment, agarwood forms only when affected by certain external factors, such as lightning strike, animal grazing, insect attack or microbial invasion, typically around wounded or rotting parts of the trunk [

7,

8]. Agarwood formation occurs slowly and infrequently in old trees and the supply of agarwood from wild sources is far less than market demand. Because of its immense value and rarity, indiscriminate cutting of trees and overharvesting in hope of finding the treasured resin has led to the depletion of wild trees [

9,

10]. Eight

Aquilaria species, including

A. sinensis, were listed on the IUCN red list as endangered species [

11]. All species of

Aquilaria have been placed on the Appendix II list of the Convention on International Trade in Endangered Species of Wild Fauna and Flora since 2004 [

1].

Efforts have been made to preserve natural

Aquilaria populations [

12] and to increase agarwood supply, and include developing the cultivation of

Aquilaria species and to intentionally injuring the cultivated trees to produce agarwood. In Indonesia, Cambodia, Thailand, Vietnam and some other countries,

Aquilaria plantations have been established [

13]. In China, over 20 million

A. sinensis trees are widely cultivated in Hainan, Guangdong and Yunnan provinces.

Farmers in these countries have gained some experience in the treated production of low- grade agarwood. Wounding methods like axe wounds, severe bark removal and nailing have been applied [

1,

2,

3,

8,

11,

13]. China had developed various artificial agarwood-inducing methods before the Song dynasty (A.D. 960). The partial-trunk-pruning method and the burning-chisel-drilling method were often used by Chinese famers in recent decades. The fungi-inoculation method was invented by Tunstall in 1929 [

20], and was introduced in China in 1976. Accordingly, we summarize those three methods as existing agarwood-producing methods. These methods require a long time for agarwood formation, but produce a low agarwood yield. Additionally, the resin produced in a short time in this manner is deemed to be of inferior quality [

14].

To date, some comparatively new and efficient methods have been developed in Vietnam by Blanchettefrom from the University of Minnesota, and these have been called cultivated agarwood kits (CA-Kits) [

7]. The main principle of this process is to drill holes in the tree trunk and keep the wound open by putting a small piece of plastic pipe in the hole, and then inoculate different chemical media into the wound. With the advantage of easy evaluation of discoloration area, this chemical treatment represents a great improvement compared with the traditional physical wounding methods.

However, no techniques for inducing qualified agarwood for wide use in plantations have been well established. Here, the term qualified agarwood means those agarwood samples that are up to the

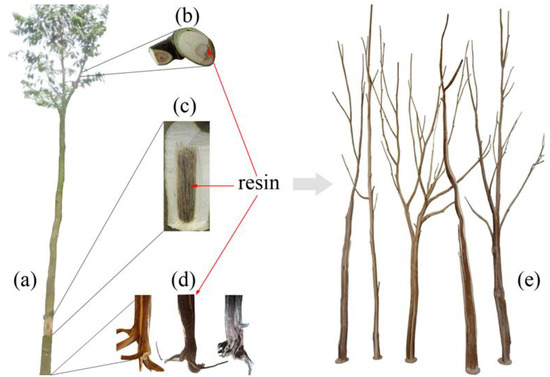

Chinese Pharmacopoeia standard in China. Our lab has developed a simpler and efficient method to induce qualified agarwood formation, called the whole-tree agarwood-inducing technique (Agar-Wit) [

15], in which simple and cheap transfusion sets are adopted. We inject agarwood inducers into the xylem part of

Aquilaria trees through these transfusion sets. Due to water transportation, the inducers are transported to the whole body of the tree, thus forming an overall wound in the tree, and as a result, agarwood is finally formed in the

Aquilaria trees in a short period of time.

To evaluate the agarwood quantity and quality induced by the Agar-Wit, the harvested agarwood was analyzed and compared with that produced by the three existing agarwood-inducing methods. The alcohol soluble extractive content and thin layer chromatography required in

Chinese Pharmacopoeia [

16], the essential oil content and its constituents were all measured.

2. Results and Discussion

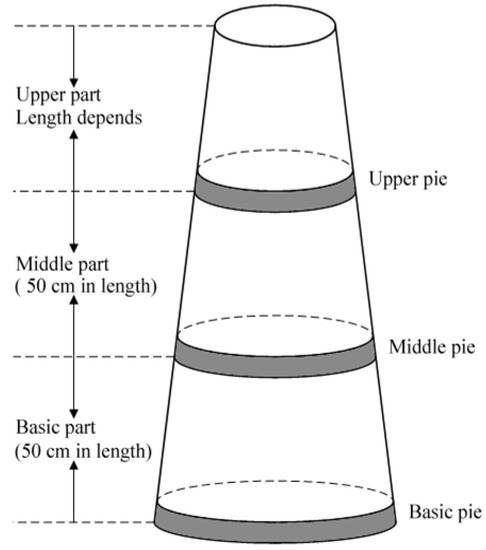

2.2. Agarwood Yield Per Tree

In the Experimental section, the formula (1) for estimate of agarwood yield per tree is an ideal model. For an ideal estimation, the stem of most of the trees of A. sinense can be thought to be symmetrical. What’s more, the ratio of agarwood is constant along the length of the trunk (). After investigating many trees with Agar-Wit, we found the length along the stem to form agarwood was about 1.5 to 2 m from the transfusion hole. If a tree has a long stem, agarwood inducers need to be made about every 2 meter along the stem to make sure high yield of agarwood.

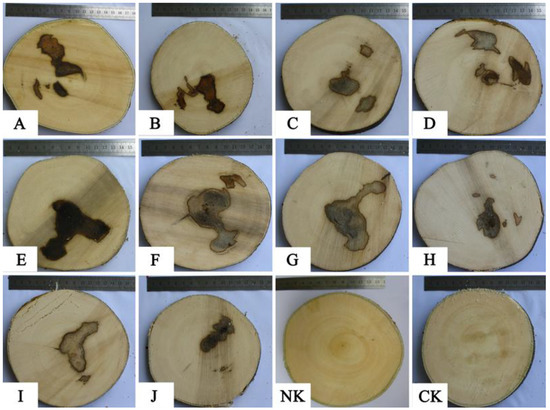

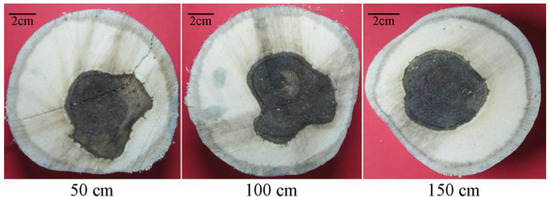

Figure 5. Sections in the height of 50 cm, 100 cm and 150 cm from the same tree.

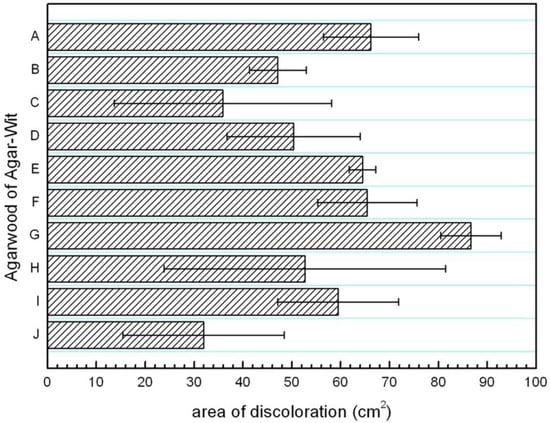

The area of resinous part was measured in the horizontal section. The average area of resinous wood of the ten samples treated by the Agar-Wit with different inducers ranged from 31.93 cm2 to 86.65 cm2 (). The average discoloration area of agarwood induced by Inducer G was significantly larger than those by Inducer B, C and J.

Figure 6. The discoloration areaof wood pies sampled at 50 cm from base in trees induced by ten different Agar-Wit inducers. Results as means±STD (n = 3).

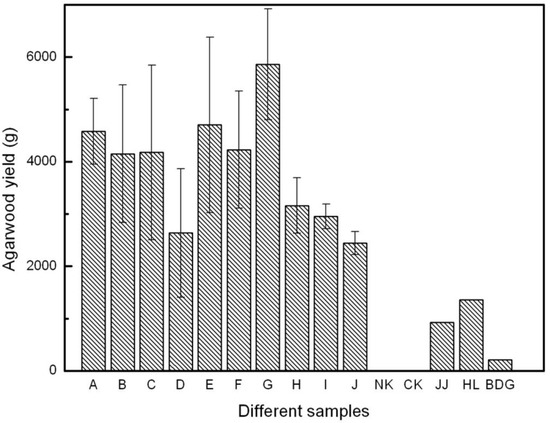

Agarwood yield per tree, treated with different inducers, was estimated according to formula (1), ranging from 2,444.8 g to 5,860.7 g (). The agarwood with Inducer G showed significantly better results in terms of the average discoloration area and average yield. The existing agarwood-inducing methods also induced agarwood formation, but resin was only found around the wound surfaces. The agarwood yield per tree treated with the existing agarwood-inducing method was measured to be 926.4 g, 1,359.7 g and 208.5 g, respectively, by PTP, BCD and FI (). The yield per tree by Agar-Wit was 4 to 28 times higher than that of PTP, BCD and FI. No resin formed in the NK and CK samples.

Figure 7. Agarwood yield per tree treated with different agarwood-inducing techniques. Results as means±STD (n = 3).

2.3. Quality Characteristics

2.3.2. Essential Oil Content

Almost all oil from the induced agarwood with the color of yellow to brown and gave out a peculiar aroma similar to that of wild agarwood oil. The wood oil from CK and NK was white. As shown in , the oil yields of agarwood obtained by the Agar-Wit ranged from 0.14% to 0.247%, showing no difference among them. These values were close to those of the two wild agarwood, which were respectively 0.345% and 0.204%. The oil yield of the agarwood obtained by BCD was 0.199%, and that by the other two existing methods was less than 0.1%, close to those of NK and CK, while far less than that by Agar-Wit.

Table 1. The oil yield of all the samples (%).

2.4. Essential Oil Constituents

In general, all agarwood oils are complex mixtures of aromatic compounds and sesquiterpenes [

17,

18]. According to our previous study [

19], seventeen main components () including benzylacetone and sixteen sesquiterpenes were chosen to evaluate the quality of all the collected samples in . The relative percentage of these sixteen sesquiterpenes of essential oil in the agarwood produced by Agar-Wit ranged from 47.43% to 52.78%, a little bit less than those of the two wild agarwood samples (71.48% and 62.35%). Guaiol, α-copaen-11-ol, baimuxinal, guaia-1(10), 11-dien-9-one and eremophila-7(11),9-dien-8-one were the five compounds with relative percentages higher than 5% in the two wild agarwoods. Similarly, the agarwood produced by Agar-Wit also had high percentage of these five compounds. The agarwood obtained by Agar-Wit had a higher percentage of benzylacetone (6.44%–10.07%) than wild agarwood (2.34% and 2.39%) as well as agarwood obtained by other existing agarwood-inducing methods (1.51%, 2.10% and 2.70% by PTP, BCD and FI, respectively). BCD and PTP respectively induced the sesquiterpenes content of 57.38% and 52.03%, and they had a high percentage of guaiol, α-copaen-11-ol, and baimuxinal. The oil composition of agarwood by FI was different from that of wild agarwood. The seventeen components only made up 37.69% of its essential oil, while

α-eudesmol, which is not the leading compound in the essential oil of wild agarwood, ranked the highest (10.12%). Obviously, these seventeen compounds lacked or only shared a small percentage in the NK (8.25%) and CK (8.47%), in which fatty acids amounted to a high percentage (6.02% and 49.47% in NK and CK, respectively).

2.5. Discussion

2.5.1. High and Steady Yield of Agarwood Produced by the Agar-Wit

Neither wild

Aquilaria trees nor cultivated

Aquilaria trees can form agarwood without wounds caused by certain external factors, such as physical injury, insect attack or bacterial/fungal infection. It will take several years for an

Aquilaria tree, which is still alive after wounding, to form agarwood around the wound [

14]. Agarwood production occurs naturally to only 10% of

Aquilaria trees [

20]. To reduce the dependence on wild agarwood,

Aquilaria species have been cultivated on a large scale, and wounding methods have been used on healthy trees to produce agarwood [

2,

3]. To maximize agarwood production and quality in plantations it is important to use an agarwood inducing method that produces a product steadily with high yield and good quality.

Table 2. Relative percentage composition of the essential oils of agarwood.

Farmers and researchers in different Asian countries have tried several wounding methods to produce agarwood, including axe chopping, nailing, and holing [

2,

3]. These methods often take a long time, with generally poor yield and quality in the agarwood produced. Concerning the existing agarwood-inducing methods for

Aquilaria trees, few reports focused on agarwood yield and quality evaluation [

7,

21]. To our knowledge, there is no one agarwood-producing method used widely in Asia. In southern China, over 10 million

A. sinensis trees have trunk diameter (Ф = 10 cm) sufficient for agarwood-inducing. However, due to the lack of reliable, steady and high yield agarwood-producing method, these trees can’t be ‘changed’ into valuable agarwood. According to our research, the agarwood yield per tree by the BCD method is higher than that by the PTP method as well as by the fungi-inoculation method. By the novel Agar-Wit, the yield per tree reached 6 kg after six months, 4 times higher than by the BCD method, 6 times higher than by the FI, and 28 times higher than by the PTP. All operating steps of the Agar-Wit reported in this paper, including drilling holes and installing transfusion sets, took no longer than 10 minutes per tree, and required no follow-up processing steps. The agarwood inducer was conveniently injected into the xylem of

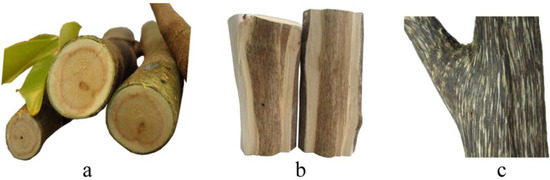

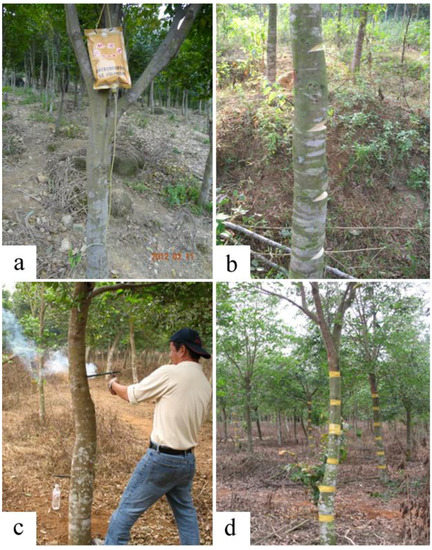

A. sinensis trees through the transfusion sets ( and a). Due to water transpiration pull, the agarwood inducer was transported to the whole tree and led to wounds in the whole tree. This wounding led to agarwood formation in the whole tree from the trunks to the roots and lateral branches. This is the first report concerning steady, expected and high-yield technique for agarwood production in the

Aquilaria genus. The external wounds caused by the existing agarwood-inducing methods, such as PTP method and BCD method, are often detrimental to tree growth, where in some cases cause

Aquilaria trees to wither and die, or be blown down by a gale. The novel Agar-Wit is less harmful and

Aquilaria trees continued to grow naturally (a). Comparing with the CA-Kit [

7], Agar-Wit is more advanced and simpler. The CA-Kit should drill many holes in the tree trunk with complex operational approach, from the bottom up to top of the stem. What’s more, agarwood can be induced and formed around the holes with the CA-Kit.

2.5.2. Qualified Agarwood Produced by the Agar-Wit

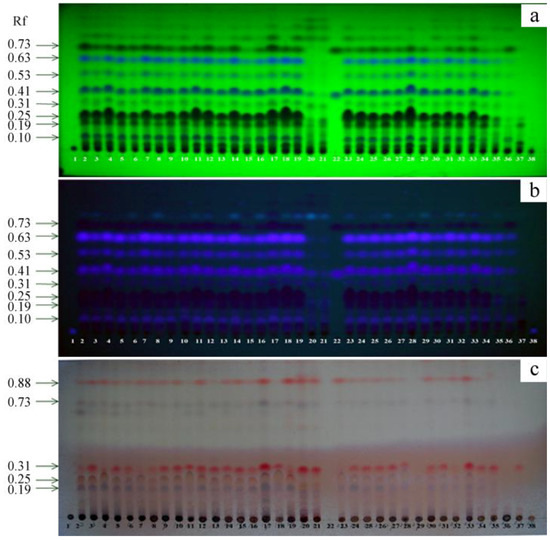

Producing agarwood with similar quality to wild agarwood is another important consideration for an agarwood-inducing method. Up to now, no standard agarwood quality assessment system is available for the whole agarwood industry. According to the previous research [

2,

3,

16,

19,

22], we believe that the thin layer chromatograph fingerprint profiles, alcohol soluble extractive content, content and compositions of essential oil may form a comprehensive system for agarwood quality evaluation by the Agar-Wit.

The agarwood extracts have been reported by several research teams [

23,

24,

25] to find out the chemical constituents of agarwood. Sesquiterpenes, benzylacetone and chromone derivatives have been reported to be the major constituents of resin [

17], with volatile sesquiterpenes regarded as aromatic constituents [

26]. In this study, benzylacetone and 16 main sesquiterpenes compounds were chosen as an index for quality, forming the basis of comparison for all agarwood samples listed in . Benzylacetone and some chromone derivatives are pharmacologically active substances of medicinal agarwood. For example, benzylacetone is used for relieving asthma as antitussive and expectorant [

27]. Chromone derivatives have antiallergic activity and show cytotoxicity against human gastric cancer cell line (SGC-7901)

in vitro [

28]. The agarwood formed after Agar-Wit induction contained characteristic chemical constituents such as benzylacetone, sesquiterpenoids and 2-(2-phenylethyl)chromone derivates, similar to the two samples of wild agarwood.

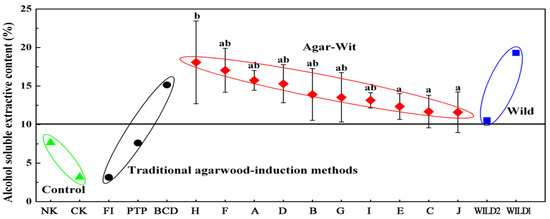

The test of alcohol soluble extractive content and TLC fingerprint profiles indicates that the agarwood produced by the Agar-Wit could surpass the required standard of medicinal-use agarwood in

Chinese Pharmacopoeia [

16].

In a previous experiment [

29], we obtained two agarwood samples 20 months after Agar-Wit treatment in

A. sinensis. They had very high quality similar to wild agarwood in terms of chemical constituents, alcohol soluble extractive content, and essential oil content. With ideal texture and desirable resin lines, they had a strong fragrance resembling the smell of honey or concentrated sugar, and had a bitter and pungent taste after chewing. Thus they were further classified as

tagara by agarwood collectors. Their average levels of alcohol soluble extractive content (g/g) were 19.65% and 22.13%, respectively, exceeding that of wild agarwood samples. The contents of essential oil (g/g) were 0.30% and 0.36%, close to or exceeding that of the wild agarwood. The relative percentages of the sesquiterpenes in the essential oil were 75.41% and 70.08%, respectively, approximating the levels found in wild agarwood. Taken together, the agarwood formed 20 months after Agar-Wit treatment had higher quality than the wild agarwood. We suggest that, using our Agar-Wit, qualified agarwood may be produced from

Aquilaria trees in 6 months, and high-quality agarwood may be obtainable if prolonging the agarwood-formation time appropriately.

2.5.3. The Prospect of the Agar-Wit

Six months after Agar-Wit treatment, agarwood was formed in A. sinensis trees. With high yield and high quality close to wild agarwood, the induced agarwood could be used as raw material for medicine as well as essential oil extraction. When the agarwood-formation time was prolonged to 12 months or 20 months, higher-quality agarwood was produced. Moreover, agarwood was formed in the whole tree due to water transpiration in Aquilaria trees. Such big-sized and unique-shaped agarwood () could be carved and processed into art work such as sculptures and rosaries, further enhancing the added value of agarwood.

The Agar-Wit can produce high-quality agarwood at a high and steady yield. This efficient candidate technique has been patented in China (CN101755629B, CN101731282B) [

15,

30] by our laboratory, and PCT applications have been filed for Vietnam, Malaysia, Philippines, India and Indonesia (PCT/CN2012/071599). Its application has also been submitted in Cambodia, Bengal and Burma. So far, the Agar-Wit has been applied on 100,000

A. sinensis trees in Guangdong, Hainan, Guangxi, and Yunnan provinces (). It has also been used in some districts of Vietnam, Cambodia, Indonesia and Malaysia. The combination of the Agar-Wit and the big cultivation areas of

Aquilaria trees in Asia will not only consecutively supply more high-quality agarwood and essential oils to the international markets, but also protect wild

Aquilaria trees.

Figure 9. Agar-Wit is popularizing in an A. sinensis plantation of Hainan, China.Trees were induced with the Agar-Wit method at age 6 years.The blue transfusion bags on each tree contain the inducers which are delivered by tube to the xylem capillary tissues through a 5 mm hole drilled at 50cm above ground level.

Compared with high-grade wild agarwood collected from local markets, the Agar-Wit-induced agarwood had some differences in color, unit weight, and aroma. Alcohol soluble extractive content has been regarded as an index for grade partition, between first (25–30%), second (20–25%) and third (15–20%) class agarwood. The agarwood obtained by the Agar-Wit in this study attained a maximum of third-class (), so further opportunity exists to refine the method such as prolonging production time, to increasing treatment frequency, and to improving inducers (i.e., by combining inducers with fungi inoculation for example). Moreover, as agarwood has various applications, there may be opportunity to establish different agarwood formation methods for different end uses.

0 comments:

Post a Comment